MONiTOR Drill Hole Counter

MONiTOR Drill Hole Counter

MONiTOR “Drill Hole Counter” is designed to identify and count any drill holes on a panel. MONiTOR is implemented on PLC-based technology by using SMART Sensors. (No frame grabber)

Drill Hole Counter Systems

Brochure: PDF

MONiTOR “Drill Hole Counter” is designed to identify and count any drill holes on a panel. MONiTOR is implemented on PLC-based technology by using SMART Sensors. (No frame grabber)

The CCD Cameras are equipped with embedded LED full-color illumination. Each camera covers a 450mm field of view. Up to 12 Sensors can be operated on one line (with one cable - POWERLINK), four lines can be controlled with one PLC. No calibration of parts, only one time learning of Decor once with the first startup.

Technical Specs:

Transport Speed: 60 m/min, Automatic Adjustment on various Speed, Encoder Controlled

Transport Media: Roller, belt, band conveyor,

Gap Detection: 80mm gap for detection required

Max. Panel Dimensions: W: 2600, L:6000 H: 120 mm (Standard)

Surface: Unicolor and light pattern

Vertical Movement and Slippage Compensation: Yes

Camera Focus Distance: Adjustable, Sweetspot at 420mm

Camera Calibration: Auto Focus adjustment during calibration

Illumination: LED Full-Color Camera embedded, external LED Illumination strip light.

Orientation Requirements: No Orientation Alignment Required

Power: 24 VDC 5 Amps

Output: Relay output (System ok and Alarm)

Safety Class: All Sensors IP65

Temperature: 0-45 degrees Celsius

PLC Cabinet Size, 400x400x210mm

HMI: User Terminal

Possibilities of Detection: From Top and Bottom surface, Optional: Left, Right, front and Trailing edges

Integration: Full Integration into product lines with Automatic article change

Timing: Standard interface, evaluation in-between 0.5 seconds after passing.

Calibration: Up to 9999, different articles can be configured by teach-in, manual, or automatic selection.

Scope of Delivery

All parts used for MONiTOR are off the shelf products (encoder, light barriers, PLC, Smart Sensor, and Illumination) - always latest state of the art technology. All Service and part replacement can be done by in house personal.

MONiTOR can be adopted with thickness sensors. Typically TRIANGULATION sensors are used with analog output.

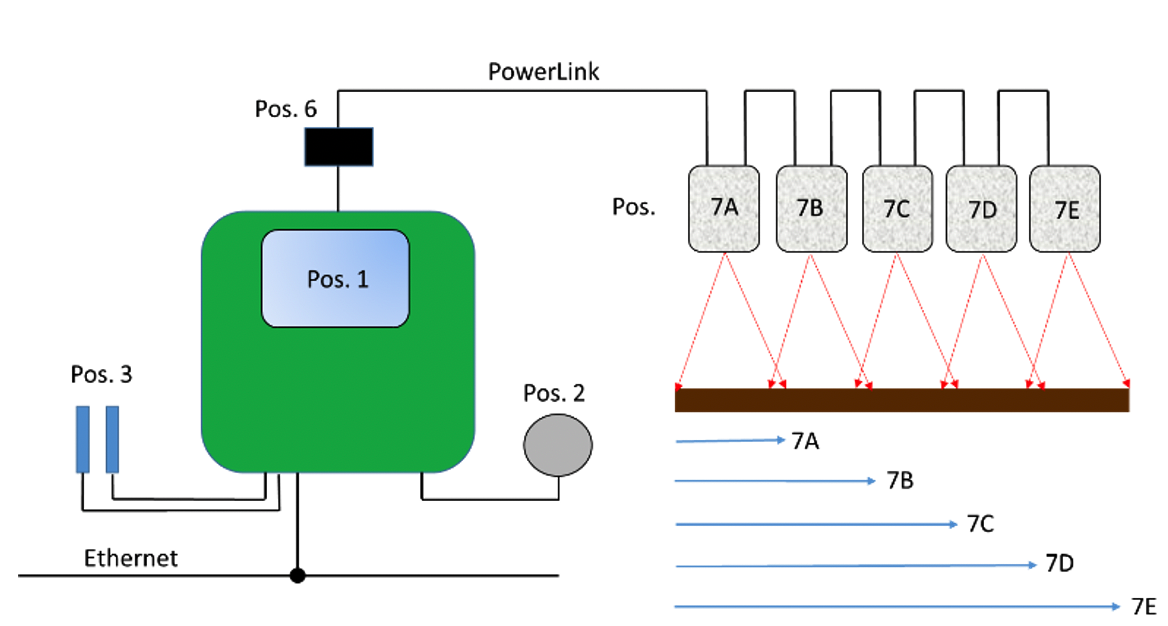

Industry Standard PLC Architecture

Pos. 1 - PLC Cabinet with Terminals for light barriers, Encoder, Power supply, Ethernet, Powerlink, and 2xUSB.

Pos. 1 - Touch Display 256mm, 2x USB 24VDC

Pos. 2 - Encoder wheel 160mm Diameter, with 5.000 T/U, 5m Cable, resolution, 0.1mm

Pos. 3 - Light Barrieres, Panel detection with 5m Cable

Pos. 7 - Up to 12 pcs. Smart Cam Sensors, 450mm FOV per Camera

Pos. 6 Powerlink Adapter, 24VDC with 20M Power Link Cable.

Smart Hole Detection

Samples of detectable holes filled with dust and clean holes, darkest and brightest decors

Dust Detection Test Example

LIVE TEST with a sample with 24 holes, 2 holes full of dust. All 24 holes have been detected. The system detects holes with or without dust – from 3mm till 50mm.

Comprehensive Scan Results

LIVE TEST with results: each detected hale identified with x and y coordinates, gray scale value and area witch is related to the diameter of the hole.

Example Line Install

Application on roller conveyor, speed 30m/min. Inspection from top and bottom. One camera sensor for500mm field of view. Maximum 12 cameras in one row (6m)

Setup example for US customer:

Thickness in 2 lines, left and right. Sensor from top and bottom. Accuracy better than 0,5mm. Conveyor speed 120m/min. Thickness from 0,1mm up to 120mm. Any color.

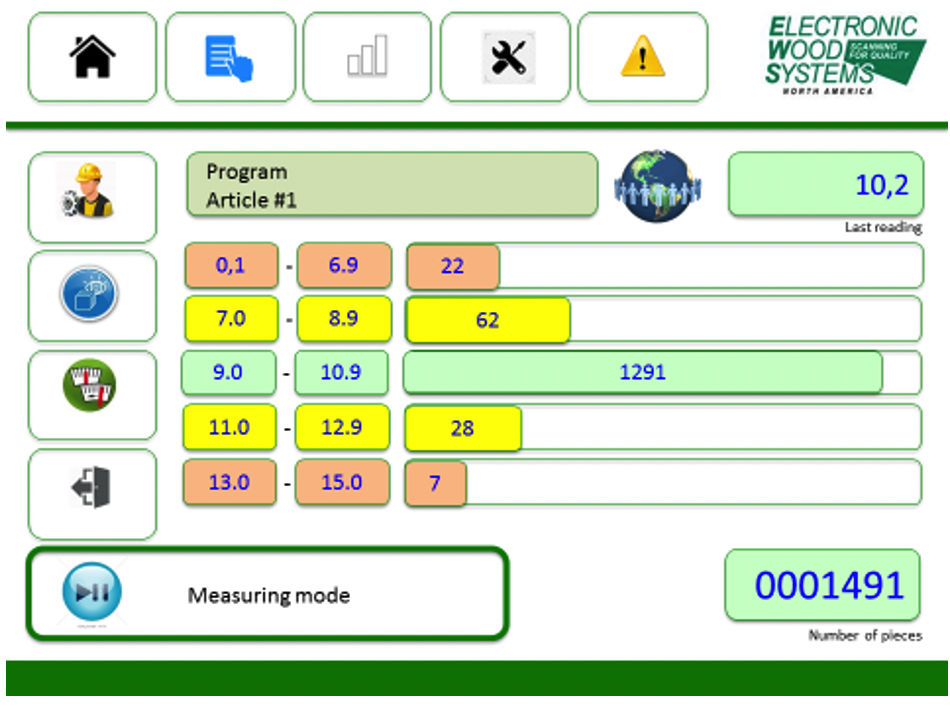

User Interface Example

This screen shows the distribution of the single results in 5 ranges.

Easy Output Setup

Every range can be dedicated to a relay output or an analog output 4-20ma.